Rating of the best load cells for 2025

Pressure and weight strain gauges are those devices from the field of weighing technology that are capable of converting the mechanical deformation of objects and bodies into a conventional electrical signal, which subsequently allows you to determine the level of compression / extension of a certain body. By itself, such a sensor is a resistive transducer and is positioned as one of the main components of high-precision weighing equipment. These devices are used in any electronic type scales: from household floor scales to ultra-precise laboratory ones.

The principle of operation of the strain gauge is as follows: when an object is placed on the scales, under its influence (weight) the resistor on which the strain gauge is installed changes (deforms).In turn, the sensor measures the force and strain of the resistor and transmits this data to the control board. Thus, the weight of the item on the loading platform is calculated. In weighing equipment, one or more sensors can be used.

Correctly, such sensors in the engineering environment are called weight meters for scales, and in the common people they are called "beams".

Content

- 1 Main Features

- 2 More about existing structures

- 3 The main difference between a 4-wire sensor and a 6-wire sensor

- 4 Holes in the load cell and their functional purpose

- 5 Connecting a Strain Gauge: Shielding and Grounding Issues

- 6 Competent approach to the selection of strain gauges

- 7 Rating of the best strain gauges for 2025

- 8 Conclusion

Main Features

Any load cell has a certain set of characteristics that affect the scope and limits of its application. These include:

- "RLM" or the maximum measurement limit is the maximum force that the device can fix. In fact, the sensor itself, of course, has an extended margin of safety, but in order to obtain accurate data, it is not recommended to exceed the NPI indicator set by the manufacturer. If ultra-high-precision results are required, then it is necessary to use a device with an additional NPI.

- According to their design, these devices can be divided into several types - bridge and single-point, beam and bellows, column and S-shaped, as well as washer. The use of a particular type of design will depend on the purpose of the weighing system in which the device is supposed to be used, and it is also necessary to take into account the features of the future location of its location.

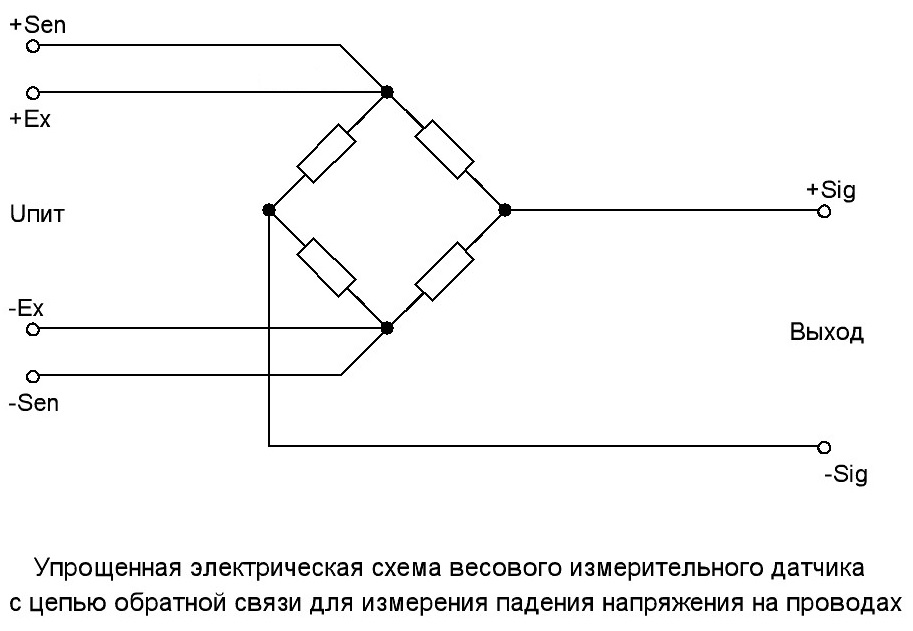

- According to the connection scheme, strain gauges can be divided into "four-wire" and "six-wire". The first scheme is used in standard cases and under normal conditions, and the second is used when there is a significant difference in the resistance of the cables of adjacent sensors, because it allows you to compensate for their electrical resistance.

- Accuracy class - for the described devices it is quite wide and according to OIML R 60-2000 (State system for ensuring the uniformity of measurements in the Russian Federation) it usually varies from D1 to C6. The class C3 is the most popular in terms of breadth of application, which is approximately equal to a statistical error of 0.02%. The use of devices with a smaller error requires a specific justification. Among other things, the weighing terminal itself can also affect the measurement accuracy.

- The material of manufacture of the device - as a standard, aluminum, alloy steel or ordinary "stainless steel" are used for this. Speaking of different designs, it can be noted that single-point, as a rule, are made on an aluminum base, but the rest of the models prefer alloy steel. "Stainless steel" is considered a more expensive material and is used for devices that are used in critical industries, for example, in the food industry.

When selecting a sensor for use for specific purposes, it is also necessary to pay attention to additional characteristics, which include:

- Electrical protection class;

- Working temperature range;

- Working gear ratio (abbreviated "KRP");

- Maximum possible supply voltage;

- Input/output resistances;

- Cross-sectional diameter and length of the electric cable.

More about existing structures

In general, the described device is a single elastic system consisting of a resistor and an electrical circuit, which is connected to a weighing batcher. When the resistance of the resistor changes, the strain level is set, after which the data obtained are transformed into the required mathematical and physical quantities and displayed on the scales display. This is how all electronic weighing equipment functions. Its sufficient accuracy will be maintained even in the event that one of the sensors fails, because the schemes used today involve duplication of measurements.

Depending on the type of the weighing bowl (or rather, the load receiving platform), there are the following types of strain gauges:

- Console type - a system with a measuring limit of up to 7 tons is used as measuring elements;

- Single point devices (single point), i.e., working on one sensor - they are used for dosing, filling and other operations where a large load is not required;

- S-shaped devices - they are intended for bunker-type equipment and proportionally convert the mechanical force of tension / compression into an electrical signal;

- Cylindrical devices - used in multi-ton control and measuring systems;

- High temperature devices - used in the manufacture of measuring instruments that operate in extreme ambient temperatures, for example, in the smelting or metallurgical industry.

The main requirements for strain gauges are moisture resistance, low susceptibility to aggressive environments, and calculation for a long service life. In addition, the sensors must be sensitive to any increased mechanical load.

The main difference between a 4-wire sensor and a 6-wire sensor

If the dimensions of the weighing equipment itself are too large, then it may happen that the connection between the sensor and the analog-to-digital converter of the equipment will be made using extended wires. Therefore, the electrical resistance of the wires themselves will begin to affect the readings.

This problem can be resolved in two ways:

- Use wires of the same length inside the structure, then the error arising due to resistance and unintentionally introduced into the measuring circuit will be known and can be compensated at the signal input to the analog-to-digital converter;

IMPORTANT: On the weighing device "MASSA-K" of the "VT" series, "know-how" was applied, and the converter was installed directly on the sensor, which made it possible to do without wires and solve the issue of resistance. However, at the engineering level, a miscalculation was made, namely: the calibration toggle switch was not moved beyond the boundaries of the load cell, which led to the complication of verification procedures.

- It is necessary to supplement the measuring circuit to check the resistance of the wire for a voltage drop and to dynamically correct the error from the resistance that is introduced into the measuring circuit.

Holes in the load cell and their functional purpose

Without these holes, the total load would be equally distributed over the entire surface, and, accordingly, it would be more difficult to establish the deformation. Due to the fact that the resistors are placed in the places where the greatest stress is concentrated, the place of integration of the latter is specially made thin so that the load applied to the edge of the beam would be expressed to the maximum in these places. Thus, the orientation of the resistors is relative to the thinnest point.

Connecting a Strain Gauge: Shielding and Grounding Issues

An important issue in creating a successful and accurate weighing system using load cells is the organization of shielding and grounding. A competent solution of such a problem is the key to the correct functioning of the tensometric device in the field of low-current signal generation. At the same time, device cables must have a shielding braid that would protect them from electrostatic and other interference, provided it is properly installed.

The main and inviolable rule in this case should be the principle of avoiding "earth" loops, which means the need to ground the device at ONE and COMMON point. If you connect the cable screen at both ends, then the occurrence of a loop is inevitable. Thus, if the sensor body is securely connected and correctly fixed to the screen, then this will be enough, otherwise, it is possible to connect the screen to ground from only ONE of any end, for example, in the electrical panel. It is worth remembering that it is highly not recommended to use "neutral" as a "ground electrode".

If the sensors are connected in parallel, then you must not forget to connect the screen cable braids to each other, using the associated terminal contact in the junction box. After connecting, immediately "ground" them simultaneously with the body of the box itself.

Also, on ONE side, it is necessary to connect the common cable passing from the device to the junction box to the ground, while the formation of an "earth" loop must not be allowed. It is preferable to implement this circuit from the side of the receiver, i.e., near the entrance to the measuring device.

Right on top of the sensor cable insulation (approximately 4-5 cm from the equipment terminal), it is necessary to snap in a ferrite filter in order to block various interferences on the "ground". These filters are available for cables of various sizes and diameters. They can also be installed on other extended lines, such as RS-485, both on the transmitter and receiver. Sometimes it may happen that the inductance of a single filter may not be enough. Then it will be necessary to additionally and sequentially snap the filters at a certain distance from each other. This will increase the inductance to the desired level and reliably reduce the level of interference.

Competent approach to the selection of strain gauges

Due to the fact that strain gauge devices are not particularly complex in their design, it is better to focus on the price, and not on the manufacturer, when buying. Thus, although today's market is full of various price and brand offers, there is no big difference between economy class and premium.Expensive sensors should be purchased only when they are really needed for high-precision measurements, for example, in the food industry or for laboratory experiments. Otherwise, this purchase will not require large expenditures and will cost the standard price relative to standard measurement errors.

Regarding the Asian manufacturer of the products in question. As the analysis shows, the measurement accuracy of sensors from Taiwan, China, Korea is in no way inferior to the most popular firms. However, the material of their manufacture is often not durable and it happens that the deformation of the beam on Chinese devices can be seen with the naked eye immediately after a couple of several measuring procedures.

Rating of the best strain gauges for 2025

Budget options

3rd place: "CAS BSA-1"

The model is intended for use in electronic scales at public catering establishments and in grocery stores. It has an improved design, access to the analog-to-digital converter (ADC) is carried out through a single wire, which does not cause a difference in resistance. More like a spare part.

| Name | Index |

|---|---|

| Manufacturer country | South Korea |

| Structural type | Cantilevered |

| Weight, kg | 0.23 |

| Dimensions, mm | 190x58x53 |

| Price, rubles | 2100 |

- Small dimensions;

- Increased accuracy;

- Connection to the ADC with one cable.

- Narrow focus of application.

2nd place: "100kg-3T"

Multifunctional sample of S-shaped design. It can be used in various types of scales designed for medium loads. Easy to install, can be paired with other sensors.With the help of a stranded wire, stable communication with the ADC is ensured.

| Name | Index |

|---|---|

| Manufacturer country | China |

| Structural type | S-shaped |

| Weight, kg | 1.5 |

| Dimensions, mm | 94x86x35 |

| Price, rubles | 3800 |

- Multifunctionality;

- Acceptable price;

- Application based on average loads (from 1 to 3 tons).

- It is possible that the resistor is failing.

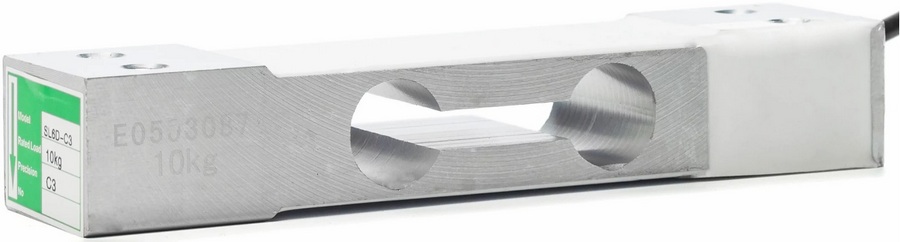

1st place: "Sierra SL6D-C3-10kg"

This sensor is designed for weighing packing and other bulk products, it is not designed for heavy loads. Extremely easy to install and made from durable alloy steel for extended life. Additionally, it has a class of protection against dust and moisture (as a separate element of equipment for weighing).

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Structural type | single point |

| Weight, kg | 1.3 |

| Dimensions, mm | 130x25x22 |

| Price, rubles | 5600 |

- Optimal equipment;

- Advanced security features;

- Extended warranty (1 year instead of 0.5).

- Limited temperature mode of operation - up to +35 degrees Celsius.

Intermediate Models

3rd place: METTLER TOLEDO CZL312

Alloy steel probe with nickel plated surface. It has a predominantly industrial purpose and is used for medium and high loads (weighing concrete mass at a construction site, weighing hot asphalt when laying a roadbed, etc.). Can work both in tension and compression.

| Name | Index |

|---|---|

| Manufacturer country | Switzerland |

| Structural type | S-shaped |

| Weight, kg | 12 |

| Dimensions, mm | 150x100x98 |

| Price, rubles | 11100 |

- Excellent value for money;

- Versatility;

- Increased load capacity (up to 10 tons).

- Small safe excess of the allowable NPI norm (no more than 30%).

2nd place: "T-100A"

This device is intended for use on relatively large loading platforms - from 80x80 cm, and can also be used in bunker and packing scales. It is an example of a single-point design, therefore it can only be used in a single version.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Structural type | single point |

| Weight, kg | 5 |

| Dimensions, mm | 45x54x79 |

| Price, rubles | 16300 |

- Increased accuracy;

- Works great on large platforms;

- Aluminum alloy body.

- Small warranty period (up to six months).

1st place: "CAS WBK-20TC"

A professional measuring device designed to check the weight of cars and various special equipment. It can be used at stationary traffic police posts in order to determine the permissible weight of vehicles for travel, as well as at customs posts.

| Name | Index |

|---|---|

| Manufacturer country | South Korea |

| Structural type | Cantilevered |

| Weight, kg | 7 |

| Dimensions, mm | 85x70x95 |

| Price, rubles | 17600 |

- Production material - stainless steel;

- High load capacity (20 tons);

- It has its own moisture protection.

- Narrow specialization.

Premium class

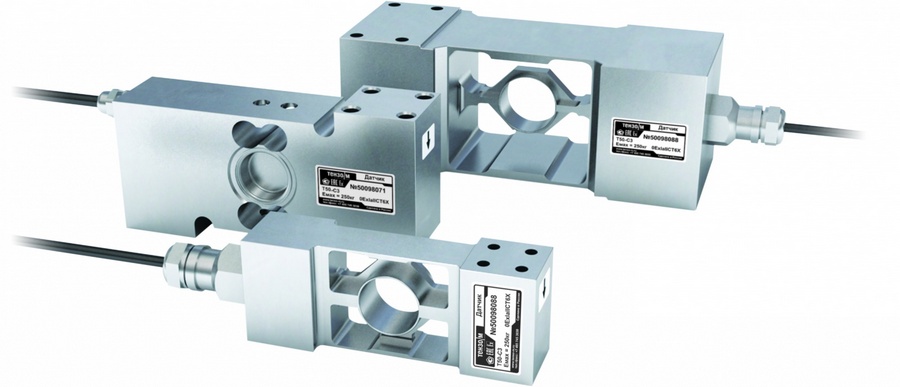

3rd place: "T-50 (1st modification)"

The design of the elastic element of this sensor allows accurate readings to be transmitted even if the load is placed on the edge of the platform. The tightness of the body is ensured by the installation of special helium gaskets. The kit comes with a protective sleeve, cover and caps.The device is designed for precise work with almost any weight - from small values to extra large ones.

| Name | Index |

|---|---|

| Manufacturer country | Russia |

| Structural type | single point |

| Weight, kg | 8.1 |

| Dimensions, mm | 76x79x95 |

| Price, rubles | 33500 |

- Versatility;

- Good staffing;

- Operating temperature range from -40 to +50 degrees Celsius.

- Not found (for its segment).

2nd place: "CAS WBK-30-D"

The model is intended for industrial use, for example, for weighing bulk and liquid materials of large volumes on enlarged platforms (determining the weight of prepared concrete in a concrete plant). Easy to calibrate, housing made of stainless steel.

| Name | Index |

|---|---|

| Manufacturer country | South Korea |

| Structural type | single point |

| Weight, kg | 15 |

| Dimensions, mm | 84x83x45 |

| Price, rubles | 57000 |

- Rugged housing;

- Increased load capacity (up to 30 tons);

- Own moisture and dust protection.

- High price.

1st place: "LSU-100"

The low profile round sensor is capable of handling extra heavy loads up to 100 tons. At the same time, the model has a margin of additional NPI of about 150%. It can function both in compression and in tension. The design uses a 4-core cable with a polyurethane protective braid, which guarantees high linearity and accuracy of data transmitted to the ADC. The system has its own moisture and dust protection, mounted according to the European standard.

| Name | Index |

|---|---|

| Manufacturer country | South Korea |

| Structural type | "washer" |

| Weight, kg | 30 |

| Dimensions, mm | 307x278x90 |

| Price, rubles | 70000 |

- Increased wear resistance;

- Ability to handle heavy loads;

- Current price.

- Limitation of the temperature operating mode at the lower limit (up to -10 degrees Celsius)

Conclusion

In order to save money, you can also order and purchase strain gauges through Internet sites. The popularity of this method is also due to the fact that on the websites of sellers and manufacturers it is very convenient to search for the desired model according to the specified parameters. Separately, it is worth noting that, unlike retail, prices on the Internet will be much lower. Moreover, if a wholesale supply of a large amount of goods is required (for example, to supply an industrial facility), then a branded specialized store may well provide a discount. In addition, sensors are a product that is hardly possible to spoil even in conditions of extremely careless shipment, so there is nothing to fear by and large.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131648 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127687 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124515 -

The best men's sneakers in 2025

Views: 124030 -

The Best Complex Vitamins in 2025

Views: 121936 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110317 -

Rating of the best spinning reels in 2025

Views: 105326 -

Ranking of the best sex dolls for men for 2025

Views: 104362 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102009