Rating of the best stone adhesives for 2025

Any stone, whether natural or artificial, does not change its properties for many, many years and looks aesthetically attractive. Such a finishing material has earned its popularity for a long time, but over the past time period it has not become less desirable. However, in order to make a beautiful cladding of any surface on its basis, a special type of adhesive composition should be used. It is from him that the ease of work and its speed, as well as the quality of the final result, will depend.

Content

- 1 Appointment of special adhesives for stone

- 2 Basic technical requirements for stone adhesives

- 3 Modern types of glue for stone

- 4 Types of mineralized natural materials that can be processed with glue

- 5 Features of gluing artificial stone

- 6 Features of gluing granite / marble

- 7 The sequence of work with glue on stone

- 8 Difficulties of choice

- 9 Rating of the best stone adhesives for 2025

- 10 Conclusion

Appointment of special adhesives for stone

Before starting the process of gluing minerals, it is necessary to decide on the method of gluing. Most professionals prefer to use substances with enhanced adhesion and reinforcing inclusions. Separately, it is worth mentioning the situation when gluing a stone to a reinforcing base - here the master will need a fair amount of care, coupled with caution. Naturally, the stone material will hold better on the reinforcement, and it is extremely difficult to destroy the integrity of the overall layout, but maximum reliability can only be achieved using special adhesives.For example, if we are talking about granite, then it is preferable to stick it on classic cement mortars. But this solution is more relevant for interior work. If marble / granite is used for exterior decoration, then the substance used for adhesion to the surface must contain special additives in its composition that suppress the destructive effects of external natural influences, for example, frost and various types of precipitation.

Basic technical requirements for stone adhesives

These working fastening substances differ and are characterized by several criteria:

- External and internal use - depending on the specific purpose, adhesives differ in composition, quantity and type of additives included in them. For the former, it is important to be safer for human health, for the latter it is more important to withstand various weather loads.

- Temperature indicators - this parameter determines the minimum and maximum temperature limits at which it is not only possible to carry out the finishing work itself, but also to operate the already made stone laying.

- Mass retention - the indicator characterizes the quality of the substance, which is necessary for fixing in a given place, despite the influence of gravity, a stone module, preventing its collapse / sliding (expressed in kilograms per square meter).

- Cyclicity of seasons - the parameter is more inherent in substances intended for outdoor processing and represents the maximum number of freeze / thaw cycles (the value should be at least 35 cycles).

- Composition - the adhesive can be one-component and two-component (the latter are more suitable for hard rocks such as granite, which is used in exterior decoration).

- The presence of special properties - this includes, for example, the adhesion force (if this indicator is relatively small, then it is preferable to use such a substance on an artificial stone, since its weight is relatively small and it is easier to hold it).

Modern types of glue for stone

Epoxy two-component

This option is good for gluing marble tiles to monolithic bases, or for gluing two stone surfaces, or when finishing concrete, brick or other durable base. The adhesive consists of a pair of complementary substances that are mixed together before starting work. Epoxy compounds perform well in outdoor conditions, they have sufficient water resistance, can successfully withstand exposure to low temperatures, while maintaining the required level of adhesion. Among them, white tinting prevails, while walking they can be transparent. Also, color tinting is allowed, carried out by adding special color additives to the mass in order to create the desired color shade, for example, to mask the seam. Two-component epoxy options are considered the best solution when working with granite. The consumption of the working mass directly depends on the thickness of the applied layer and the weight of each glued module. Standard consumption rates range from 1.8 to 6 kilograms per square meter.

Polyester

They are a mastic mass, in which there is a polyester blotch.Such substances are characterized by excellent adhesion, but they must be applied only in conditions of positive temperatures. They dry very quickly, so the application should be done in small portions. With their help, it is easy to carry out finishing grinding and seam grouting. For polyester compositions, consistency adjustment is allowed so that they can process sloping bases. To start work, it is necessary to first start polymerization in polyester adhesives by adding hardeners. These compositions can be both colored and transparent.

Cement

This version of the adhesive mass on stone is considered a classic. In its manufacture, white or gray cement of the M-400 or M-600 brand is used. Cement mortars are considered the cheapest in terms of costs. On a cement base, a composition can be made both for working with natural minerals and with artificial ones. It is able to sufficiently ensure the strength of the hitch, it can tolerate moderate weather precipitation well. The solution resists most chemicals well. Curing occurs within 6 hours, which is more than enough time to make adjustments to the finish. There are variations that dry in 90 minutes - they are used for accelerated masonry.

Types of mineralized natural materials that can be processed with glue

Such materials include the following:

- Limestone - has low strength along with low weight and absorbs moisture well. According to it, it is better to use a frost-resistant composition from the category of cement, which, in addition, can provide increased adhesion.

- Granite is the heaviest mineral and is very difficult to work with because it is prone to crumbling.For him, it is preferable to use a high-level two-component mortar, especially if sloping surfaces are to be finished. Cement options are also suitable for flooring.

- Marble - it is somewhat inferior to the previous stone, because it contains a fair amount of limestone. Marble is also glued to two-component mortars, but the presence of special strengthening additives is desirable in their composition.

- Sandstone is a fairly popular natural material, often used for facade work. The most standard cement adhesive composition will suit him.

- Quartz slate - can be used as an interior decoration, as well as for facade decoration. It also shows an excellent level of adhesion when working with cementitious adhesives.

Features of gluing artificial stone

Almost any of the modern specialized adhesives can be suitable for this material. To date, in the area of construction and finishing works under consideration, the use of gypsum decorative stone is most common. Depending only on the preferences and financial capabilities of the master himself, such material can be glued using:

- Bustilat;

- PVA;

- Acrylic;

- cement compositions;

- Putty;

- polymer sealant;

- Glue tile;

- "Liquid Nails";

- Mastic.

Features of gluing granite / marble

If granite (marble) interior decoration is expected, then the adhesive can be selected without special requirements for frost resistance:

- For flooring, any universal stone glue from the budget segment is suitable (cost from 220 rubles per 25 kilograms);

- For the kitchen / bathroom (as well as other rooms with high humidity), substances should be selected that contain additives for enhanced fixation (this information is placed in the product description);

- But for wall cladding with the type of material in question, it is better not to use universal samples, but immediately use highly specialized solutions that are especially focused on laying tiles on an inclined or vertical surface.

Special qualities of stone adhesive for outdoor use

Any type of granite/marble adhesive that is oriented to outdoor use will always have a reinforced formulation. For such work with such material, there are no universal options. The most common are cement mixtures, which include special bonding additives. After their hardening, they create a fairly strong connection. The cost of these products is affordable, it is comfortable to work with them, they can also fill in various construction defects in the form of cracks. With proper implementation of the laying of mineral material on the base, the risk of deformation of the lining is significantly reduced, and the possibility of its peeling tends to zero probability. However, a more reliable option would be the use of epoxy two-component substances. Of course, their cost is somewhat higher (about 3-4 times compared to cement ones), but they also act more efficiently, having high adhesion and excellent frost resistance. Standardly they have a milky white or transparent color. They can be used simultaneously for joint grouts, providing "treatment" of the stone in particularly difficult operating conditions. They are easy to make granite calculations in the open air in the form of mosaics or full-size paintings.

The sequence of work with glue on stone

Before starting the working process, it is desirable to degrease the surface to be treated, for which simple ethyl alcohol is usually used. Next, you need to wait until the applied substance evaporates. The next step will be the preparation of the adhesive mass. The main thing here is to knead it very high quality, while observing the proportions and consistency level recommended by the manufacturer. Curing time will depend on the type of adhesive used and the environment. It should be noted that even when working with slowly drying substances, it is desirable to carry out all work as quickly and accurately as possible, using small portions of the working mixture. In addition, it is always necessary to monitor the appearance of air bubbles in the mixture and immediately remove them - later they can cause poor adhesion of the stone module to the base. Cement samples used for laying out on the facade are quite simple to prepare. The base must be poured into a specially prepared container, then add water or a special latex composition, and mix the resulting mass to the desired density. If it is intended to be used on an artificial mineral, then re-dilution with liquid is not required.

Difficulties of choice

When buying a product in this category, you should pay attention to the following points:

- Cost - epoxy compounds are more effective than polyester and cement, but their cost is 3-4 times more.

- Type of proposed work - epoxy samples, in most cases, will be universal and can be used for both internal and external cladding.They can easily withstand the effects of destructive weather factors (moisture, elevated temperatures, frost), as well as withstand the negative effects of chemically aggressive substances (solvents, alkalis and acids). Polyester mixtures are best used exclusively indoors for interior decoration, because they do not have the above protective properties. In addition, it is simply forbidden to apply a polyester mixture to a non-degreased surface, and an epoxy mixture is quite possible.

- The need for reinforcement of the treated surface - epoxy compounds, in addition to their main function of fixing, can also fill building cracks, giving the treated base additional solidity and improving its structure. But polyester variations only work to connect the stone with the base, so they may need third-party reinforcement, lamination and reinforcement.

- Curing time - polyester samples harden quite quickly, which cannot be said about epoxy and cement products, which have a special period for adjusting the resulting calculation. In any case, the last two versions of the adhesive also have quick-drying products.

- Force load - if you distribute the resistance of fixation in terms of holding weight, then epoxy products will be in the first place, cement in the second, and polyester in the third.

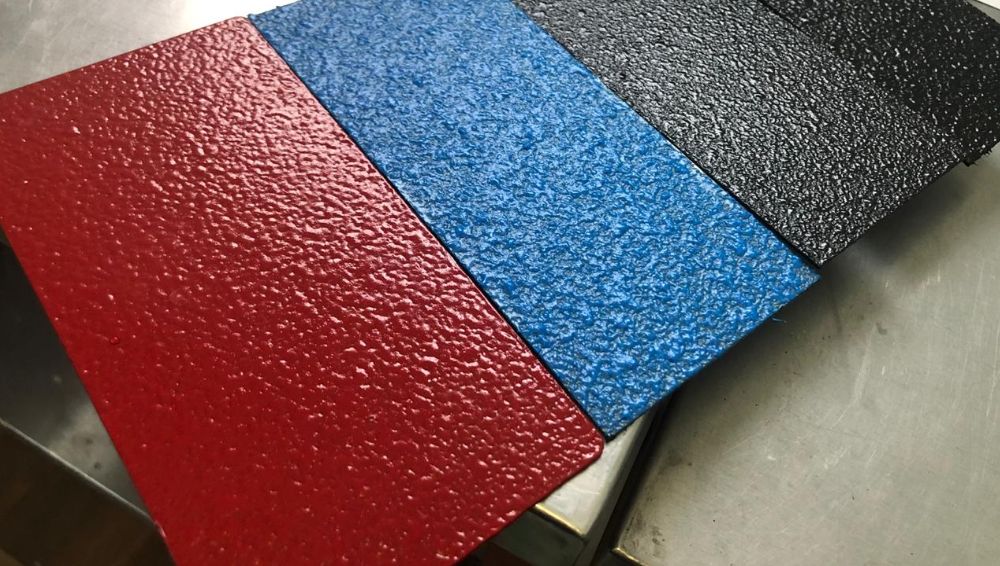

- Color - Most modern adhesives for mineral objects are either white or completely transparent. However, it is allowed to add special color additives to them, which give the whole mass the desired shade of color.

Rating of the best stone adhesives for 2025

Budget segment

3rd place: "Point 103, 290 ml, gray"

This product is also a sealant.Upon reaction, it creates a stable (holding for many years), extremely durable, non-shrinking layer of gray color. Does not contain isocyanates, silicone, solvents. Cannot cause discoloration of the surface of stone, brick, concrete, marble. Can withstand heavy loads. Recommended for many surfaces (including wet ones). Resistant to weak acids/salts, mineral oils, aliphatic fats. Application temperature — from +5°С to +25°. The recommended cost for retail chains is 438 rubles.

- Strong adhesive;

- Vibration resistance;

- Possibility of toning.

- Before use, check the tightness of the installation of the dispensing nozzle.

2nd place: "Axton inner 5 kg"

The product is a powder solution that requires subsequent dilution. It is used for laying ceramic tiles, granite and marble during interior work. The high-quality composition facilitates the process of laying and adjusting the position of the tiles. After setting, there will be no defects that require correction. All elements of the tile coating will not loosen and fall off throughout the entire service life. The substance is able to hold modules up to 45x45 cm in size or granite 35x35 cm in size. The minimum operating temperature is 5 °C, the maximum is 40 °C. The recommended cost for retail chains is 545 rubles.

- Wide temperature limits of application;

- Adequate cost;

- Possibility of correcting the final calculation.

- Not detected.

1st place: "Axton indoor/outdoor 5 kg, white"

This sample has improved technical characteristics, has an increased open time, belongs to class C2E, according to the classification of European Norms EN 12004. It is a mixture based on cement, contains special synthetic resins and chemical additives that give the product, after dilution with water, elasticity and high adhesion on traditional building foundations. The solution has a high water-holding capacity, is technologically advanced, easy to use. Elastic properties compensate for the stresses that arise between the modules and bases during their structural and thermal deformations. When facing vertical surfaces - there is no slipping of tiles. Differs in water and frost resistance. Environmentally friendly, does not contain asbestos fibers. The recommended cost for retail chains is 565 rubles.

- Has European certification;

- Supports vertical overlay well;

- Adequate cost.

- Not detected.

Middle price segment

3rd place: "Stone Age" - for decorative stone, black, 9 kg"

This universal cement composition is used on decorative stone. It can be used for both gypsum and concrete tiles, as an adhesive / grout mixture. Can be used outdoors. When developing the substance, the best gypsum binders were used, which made it possible to create a “comfortable” mixture on which decorative stone can be glued. The container contains a trowel envelope of "European quality" with a size of 53 cm, which will definitely not burst when the mixture is first loaded. The grouting process with such an envelope will speed up several times.The recommended cost for retail chains is 570 rubles.

- Large volume of containers;

- Quality additives;

- Classic black.

- Not detected.

2nd place: "Tytan for stone and ceramics, white, 310 ml"

Such an acrylic composition is reliably able to fix decorative and finishing stone and marble blanks to porous / absorbent surfaces: wood and concrete, brickwork, drywall and plaster. Seizes within 10 minutes. Moisture-resistant solution seals seams and joints between modules. Suitable for use in wet areas and outdoors. Volume - 310 ml. In the uncured state, it is perfectly cleaned with water. The recommended cost for retail chains is 810 rubles.

- Focus on restoration work;

- Work indoors and outdoors;

- Sufficient moisture resistance.

- Too small volume.

1st place: "Ceresit CM 115 5 kg"

This product is a "classic" and is used for interior and exterior surface finishing. Designed for cladding bases with tiles made of granite and marble, limestone, glass mosaics. Suitable for wet rooms, underfloor heating, swimming pools and showers, balconies and terraces. Intended surfaces are plaster, concrete and cement. When adding an elasticizer, the solution can be used for fixing tiles on chipboard, GVL, OSB, GKL, old tiles and other substrates. The mixture is made of white cement with polymer additives and mineral aggregates. It is characterized by fire resistance, does not contain toxic components and prevents the development of fungus.The maximum size of the fixed module is 60x60 cm. The service life is 1 year from the date of manufacture. The recommended cost for retail chains is 870 rubles.

- Classic and well-established composition;

- Excellent value for money and quality;

- Ability to fix large modules.

- Not detected.

Premium class

3rd place: "KRASS for concrete and natural stone, 300 ml, colorless"

This silicone adhesive sealant is used for repair, decoration and construction work. The main purpose is the sealing of heavy-duty concrete, natural stone and durable metals, glass, wood, brick, ceramic tiles, plastics and other surfaces. It is required to apply on a dry, cleaned surface with a gun. After 1 - 2 hours after application, the viscous mass becomes resistant to moisture. After 1 - 2 days, the substance acquires strength and elasticity. The recommended cost for retail chains is 1005 rubles.

- Dual purpose composition;

- Adequate cost;

- Variety of work for various reasons.

- Small volume.

2nd place: "ACRID 50 ml + 50 ml"

This modern Russian-made solution is especially recommended for gluing acrylic and quartz artificial stone. Differs in excellent quality of gluing for all types of an artificial stone and quartz surfaces. The complete set makes one tuba + 2 mixers. The recommended cost for retail chains is 1130 rubles.

- Sufficient container volume;

- Easy mixing;

- Orientation to work on artificial minerals.

- Not detected.

1st place: "ELKAY EB 25 GRANIT two-component"

This two-component composition is used on marble, granite and natural stone. Made from polyester. Designed for bonding, repairing and filling porous surfaces of marble, travertine, natural stone, ceramics, bricks and similar materials. Fast curing (3-5 min at 25°C), low shrinkage on curing, easy to use. Gives out excellent juicy color after processing by the grinder, it is chemically inert. The recommended cost for retail chains is 1200 rubles.

- Durability;

- wear resistance;

- Excellent adhesion.

- Not detected.

Conclusion

The use of stone of any type for finishing purposes is a fashionable trend among many developers. In addition, these works are also popular with architects and designers. The latest adhesive technology will allow you to attach the stone module to almost any base and make it both modern and retro. Moreover, the stone finish has always been considered the most durable and protected.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131651 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127690 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124518 -

The best men's sneakers in 2025

Views: 124033 -

The Best Complex Vitamins in 2025

Views: 121939 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114980 -

The best paint for gray hair - top rating 2025

Views: 113395 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105329 -

Ranking of the best sex dolls for men for 2025

Views: 104366 -

Ranking of the best action cameras from China in 2025

Views: 102215 -

The most effective calcium preparations for adults and children in 2025

Views: 102011