Ranking of the best fixing varnishes for furniture for 2025

By itself, wood furniture is quite expensive, because. production material is environmentally friendly. But despite a bunch of positive properties, it is subject to various deformations when exposed to various negative external factors. Thus, in order to prevent the influence of such processes on the wood base, it is necessary to take care of their prevention in time. Various fixing varnishes for furniture can serve as an excellent tool in this regard.

Furniture fixative varnish is a substance (or mixture thereof) that has film-forming characteristics and is applied to the wooden surface of the fittings.Its main purpose is to provide the wooden base with a special film that will protect it from the effects of negative external factors, while maintaining the internal structure of the integrity of the tree. Lacquering can be both the final stage in the manufacture of furniture, and one of the stages of the repair process. Products may be available as sprays or liquid mixtures for brush/roll application.

Content

- 1 Existing types of fixing compounds

- 2 Functional Features

- 3 Modern types of fixing varnishes

- 4 Differences between fixing varnish and interior varnish

- 5 Some properties of fixing compositions

- 6 A few tips for choosing

- 7 Working moments

- 8 Ranking of the best fixing varnishes for furniture for 2025

- 9 Instead of an epilogue

Existing types of fixing compounds

Fixing varnish, unlike paint, is not intended to hide the natural pattern of wood, but should “fix at the original level” its qualitative properties. Thus, it must protect the surface of the furniture from moisture, the harmful effects of UV rays, mechanical shocks and the occurrence of roughness. Not all fixing varnishes are suitable for domestic use, so you should clearly navigate their varieties in order to obtain the most effective result. In the direction of fixing properties, the varnish coatings under consideration can be divided into:

- Water-repellent - maintain the integrity of the wood base when interacting with moisture;

- Weather-resistant - resist natural precipitation and phenomena (for example, gusty winds, which eventually emasculate the surface);

- Heat-resistant - resist thermal stress;

- Shock-resistant - protect the structure from mechanical damage.

Functional Features

As a rule, fixing coatings are some combination of a special film-forming substance with an organic solvent. After drying, the surface of the furniture is covered with a transparent layer, while it can be given shades of matt / glossy sheen. All protective characteristics of a varnish product will depend on its composition, in other words, the variety. With the help of the substances in question, furniture can be transformed and retain its original qualities for a long time, whether it is assembled from MDF or chipboard, plywood or wood. Basically, fixing varnishes are designed to perform the following functions:

- Giving a special shine to surfaces;

- Protection against pests, water and dirt;

- Preservation of color qualities;

- Giving furniture strength and durability;

- Resistance to swelling/cracking over time;

- Counteraction to the conditions of elevated temperatures, various atmospheric aggressive factors;

- Masking of some surface defects (hiding small chips, scratches or cracks);

- Prevention of accidental injury to people (eg, eliminating the risk of splinters).

Modern types of fixing varnishes

Oil based

Such a substance is designed to fix the appearance of wooden furniture, giving its surface some characteristic yellowish woody tint. The structure of the substance includes a solvent, various oils and resins. In former times, the composition included linseed oil, today synthetics are used. White spirit or turpentine may also be added. Characterized by a long drying process. The resulting protective film is designed to prevent the appearance of fungus / mold, as well as fading in the sun. This coating is distinguished by moisture resistance and strength, as well as a visually attractive appearance. Excellent for processing garden furniture, fences or arbors. In cases where processing is performed at home, it is necessary to pay attention to the presence of harmful / toxic substances in the composition and use protective equipment (respirator) in the process. Also, after hardening, the treated surface can be sanded, which will add extra shine.

Nitrocellulose base

The basis of this varnish is nitrocellulose. The composition contains resins and plasticizers, organic solvents and colloxylin. This substance can be used for furniture repair work and it is suitable for application to any type of wood. It is considered very safe, does not have an unpleasant odor.The drying process is very fast - after 45-60 minutes a hard film is formed. The resulting coating has increased decorative properties and is considered the best means for fixing patterns and decorations on a wooden surface. In addition, being sufficiently durable and moisture resistant, the lacquer base can easily withstand polishing. However, it has a pronounced instability to the negative effects of the atmosphere. Hence the conclusion - this varnish is not intended for outdoor furniture. When processing, the use of protective equipment is required.

Aquatic

Such varnishes are considered the most environmentally friendly and safe, because they do not contain toxic substances at all. Recommended for processing children's furniture and furniture in medical institutions. After application, a coating is created on the surface, which is characterized by increased strength and resistance to mechanical stress. Despite their water base, these varnishes are not able to withstand the effects of moisture - again, they are not recommended for outdoor furniture. They may contain one or two components. One-component ones do not require dilution or mixing with other substances (solvents), while the latter are produced using polyurethane, which increases their strength. The most popular means of fixation include water-based acrylic formulations. In its original form, this substance is white, but after application and drying, the water base evaporates, and the remaining resin forms a transparent layer. The main advantages of acrylic are:

- Complete security;

- No unpleasant odors;

- High level of fire safety;

- Drying speed;

- Preservation of the natural structure of wood;

- Increased strength.

However, such a varnish should only be used in spaces where the ambient temperature is at least +20 degrees Celsius - otherwise the coating simply will not dry.

Polyurethane compounds

They include polyesters and isocyanates. Usually, they are made on a water base, hence it is clear that they do not contain toxic substances. They are characterized by strength, moisture resistance, elasticity, which prolongs their service life. The film is created with glossy shades, perfectly cleans and counteracts chips and cracks. They can be used for any kind of wood. They are perfectly able to withstand moisture, which makes such varnishes optimal for processing country furniture (arbors, enthusiasm, summer verandas, etc.). The polyurethane layer protects not only from water precipitation, but also from direct sunlight, as well as from temperature changes. However, there are a number of disadvantages:

- High price;

- Long drying period;

- During processing, a pungent odor is released.

Based on alkyd resins

Such varnish substances are based on synthetic resins and have the properties of strength, moisture resistance and transparency. They can be applied to any type of wood and do not depend on the conditions in which processing must be carried out. Perfect for outdoor furniture. After hardening, the surface is covered with a transparent film that is resistant to negative atmospheric phenomena. At the same time, the furniture acquires protection against mechanical damage and will be able to withstand the destructive effects of some aggressive chemicals. The disadvantages of using alkyd lacquer coatings can be called their long drying process - the full solidification of the substance occurs only 72 hours after treatment.Among other things, the product has a pungent odor, and the composition may contain toxic components - solvent, xylene, white spirit. The most resistant sample is considered to be an alkydo-urethane-based varnish, which can be used to coat not only furniture, but also parquet floors. Alkyd-carbamide products have a two-component composition and dry quickly.

Craquelure varnishes

This is a special lacquer variety that is decorative and allows you to create the look of aged furniture. This sample can be used to work with antique objects. After the processing procedure, a surface with natural cracking marks is formed. This effect becomes possible due to the fact that the coating and varnish have a different solidification period. This option is used only when appropriate for interior design.

Differences between fixing varnish and interior varnish

In order to most effectively use fixing varnish, it should be distinguished from interior varnish and take into account the operating conditions of future processing objects and the load on them. Although there are no big differences between fixing and interior varnishes, some manufacturers emphasize the exclusive repair orientation of the substance with the name “fixing”, as well as the fact that they are not recommended, for example, to cover parquet floors. As a result, fixing varnish coatings have the following main differences:

- Maximum allowable loads - the use of decorative pieces of furniture in order to preserve one or another of its drawings / patterns, which does not imply intensive use of the object;

- Gloss level - the frequent inclusion in the varnish structure of components that form a matte rather than glossy effect, because the former are less easily soiled and do not leave fingerprints on themselves;

- Operational options - for the treatment of outdoor furniture, varnishes have in their structure mandatory components that resist negative atmospheric phenomena, temperature fluctuations and frequent changes in humidity;

- Shades - fixing substances can be both transparent and tinted. The latter are responsible precisely for maintaining the color and even slightly enhance it, however, the texture and pattern of the wood remain unchanged.

Some properties of fixing compositions

- Moisture resistance as a reason for the high cost

This property does not allow moisture to penetrate into the interior of the wood structure and does not give it back (does not dry out the base), so water does not accumulate under the film layer and does not deform the coating. Such a property, of course, increases the cost of a particular sample, because it increases its fixing and protective qualities. However, it is worth overpaying the price for such properties only if furniture of a certain risk group, for example, outdoor and garden furniture, will be processed. If the furniture is supposed to be used exclusively in dry rooms, then there will be no sense in this protective quality.

- Odors and their impact on human health

If the varnish material is based on an organic solvent, then it will have a pungent odor that can cause a person to have a headache, an attack of nausea or an allergy. However, the constancy of such processes in a particular individual will speak of private intolerance and the presence of pathological processes in the human body. Naturally, substances with a pungent odor are harmful, but they simply need to be used in well-ventilated areas. At the same time, water-based lacquer substances are absolutely harmless to people. They may have some protective properties, such as UV resistance or elasticity. But they may not fully possess the required fixing qualities, for example, moisture resistance.

A few tips for choosing

In order to protect wood and fix its initial qualities, it is worth choosing the right substance for processing. The specific choice will depend on the tasks and operating conditions. It is easiest to follow the following tips when buying:

- The acquisition of professional samples with wide functionality at an expensive price is justified only in a few cases;

- Before buying, it is necessary to assess the wear and tear of the furniture and the damage existing on it;

- It is better to select a specific varnish for a specific type of furniture. For example, for tables it is preferable to use polyurethane two-component samples;

- It is worth considering the operating conditions - whether the thing requires resistance to precipitation, whether the properties of resisting mold, fungi and pests are important;

- Is a quick drying of the varnish base required;

- In cases where it is necessary to carry out work on a small scale on a small area, then for these purposes it is preferable to use a spray that is easier to apply;

- If the work is supposed to be in rooms with children or allergy sufferers, then you need to purchase odorless hypoallergenic compounds;

- The purpose of processing must justify the choice and cost - to fix drawings / patterns / images, craquelure, oil or glossy compositions are needed.

Working moments

Surface Preparation and Process

Initially, it is necessary to carefully clean the working base of the furniture from various contaminants, including dust. It should be noted that for this it is worth using a slightly dampened soft cloth or modern cleaning products. Before starting the procedure, it is imperative to wait for the base to dry before starting varnishing. The next optional, but recommended step may be to clean the working area with fine sandpaper - this way you can eliminate the slightest roughness, and the application of the varnish layer will go smoothly and positively affect the adhesion of the layer directly to the wood base. The most preferred method of application is with a small brush (for large-scale work - with a roller). Varnishing should be done in several layers (usually three are enough). It is worth remembering that each subsequent layer should be slightly thinner than the previous one. Too thick layers will cause excess color droplets to appear on the furniture. Moreover, thin layers will dry much faster.

Savings and consumption

In order to correctly calculate the required amount of varnish substance, it is necessary to make simple calculations, for which the following criteria will need to be taken into account:

- Wood surface - if the wood has small pores, then it will always require less varnish than wood with large pores. For example, ash or oak will require more varnish substance than pine or beech.

- The quality of wood sanding - a small amount of material is always spent on a well-sanded base. For high-quality grinding, it is recommended to use sandpaper with R-100 grain. The second sanding layer is best done with R-220 grit sandpaper.

- Viscosity - the density of the material will affect its consumption - the thicker it is, the more it will go away. Thus, to reduce the percentage of density, you can use the method of diluting the composition with a solvent. If the varnish material is made on a water basis, then you can dilute it with ordinary tap water;

- Application method - when spraying, the minimum consumption is achieved. However, bottled varnish is most often intended for small repairs and is not suitable for large-scale processing. The best option is to use a brush. But when working with a roller, consumption can increase significantly.

Ranking of the best fixing varnishes for furniture for 2025

Budget samples

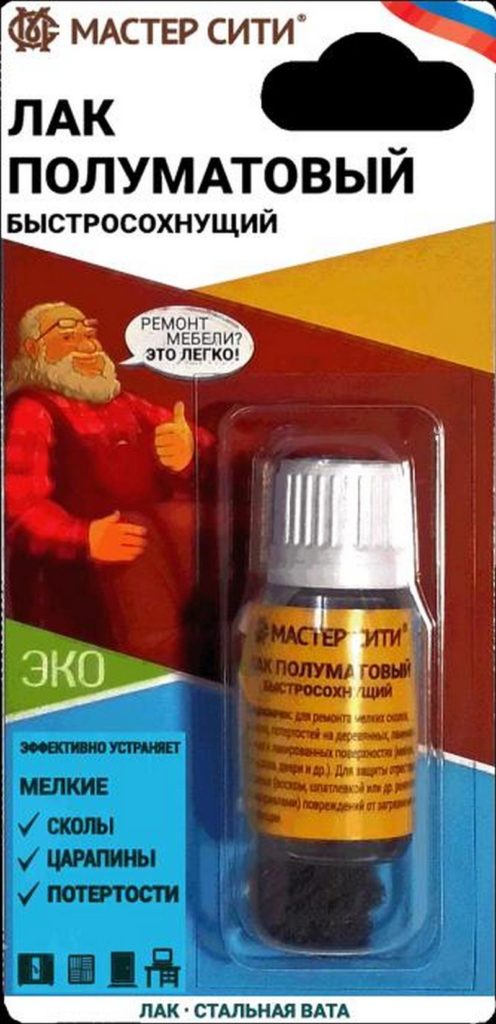

3rd place: "Quick-drying semi-matte MASTER CITY, bottle with a brush 15 ml., colorless"

This sample is intended to repair small chips and cracks, to remove scuffs and protect restored furniture from possible damage. Ideal for turning work, can be used on any type of wood. Supplied in a convenient bottle with a brush. The fixing properties are fixed with a matte shade, which counteracts the leaving of stains on the surface. The recommended retail price is 90 rubles.

- Fast drying;

- Matte shade;

- Excellent fixing properties.

- Small capacity.

2nd place: "Fixing IRFIX 20 ml 20285"

This option is used to remove various damage from both clean and varnished surfaces. The fixing quality is based on the prevention of the appearance of abrasion marks and any stubborn dirt. It has the qualities of moisture resistance, resistant to frost, drying is very fast (about 5 minutes).Requires pre-treatment of the surface with sandpaper or sandpaper. The recommended retail price is 120 rubles.

- budget cost;

- Frost resistance;

- Long shelf life - 3 years.

- Preliminary preparation is required;

- Small capacity.

1st place: "RESMAT fixing for wooden, laminated and plastic surfaces (semi-gloss)"

It is used as a means of additional fixation of restoration actions on damaged areas of furniture. Adds stability to the base to moisture and mechanical shock. It can be applied not only to wooden, but also to plastic areas. Has fast drying. Depending on the processing material, it requires a certain number of application layers. Not compatible with furniture markers (valve and alcohol). The recommended cost for retail chains is 290 rubles.

- Fast drying;

- Frost resistance;

- Ability to work with different materials.

- The composition contains toxic substances.

Middle price segment

3rd place: "Neva palette fixative (2533910), 120 ml"

A highly specialized sample designed exclusively for fixing patterns / drawings / decorations on wooden bases. Not suitable for use as a restorative material. Perfectly fixes the decor applied with pastels, oils and even watercolors. The fixing process is carried out exclusively by spraying from a spray bottle. The recommended store price is 300 rubles.

- Focus on fixing the decor;

- Simple fixing process;

- Affordable price.

- Little functionality.

2nd place: Aerosol NC Furniture Nitrolacquer DECORIX, 520 ml., Type: Oak NTR08

This nitro-lacquer is used to form a hardened finishing protective layer during restoration work and finishing of wooden furniture, baguettes, caskets, parquet, doors and even musical instruments. Its main advantages are the speed of drying and the ability to polish. After application, it creates an even and smooth base, brightly emphasizing the wood structure. Can be applied to some types of plastic and metal. The established price for retail chains is 350 rubles.

- Excellent value for money;

- Versatility;

- Multifunctionality.

- Not detected.

1st place: "V33 Furniture Water Gloss Polyacrylic"

An excellent and inexpensive sample from European manufacturers. Great for large-scale work, able to securely fix the native color of wooden furniture. Applied exclusively in two layers. Requires preliminary cleaning of the working base. Dries in 3 hours and withstands subsequent sanding with fine-grained sandpaper. The recommended price for retail chains is 750 rubles.

- High-quality restoration properties;

- Fast drying;

- European manufacturer's brand.

- Not detected.

Premium class

2nd place: "Fixing non-halo MASTER CITY, 400 ml., colorless"

It is used for leveling the level of restored and basic surfaces of furniture, as well as for restored damage. Protects against the risks of future mechanical deformations and the occurrence of persistent contamination. Easily eliminates various scuffs on old varnish coatings. The recommended retail price is 1250 rubles.

- Easy to use;

- Prevents persistent pollution;

- Adequate cost.

- Not detected.

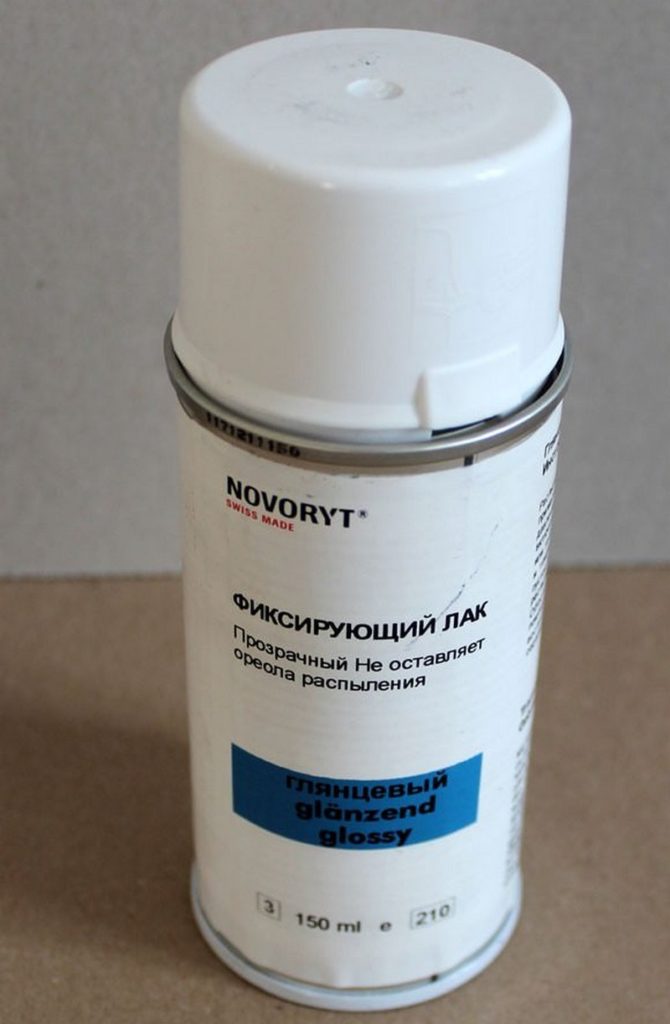

1st place: "Real-free fixing "NOVORYT"

Transparent and colorless version, based on an organic solvent. Supplied in an aerosol can and can have different shades - silky-gloss, matte, silky-matte. Suitable for both repair work and primary varnishing. Perfectly closes existing damage, protecting them from future deformations. It perfectly copes with leveling the level of gloss on any wood bases - from solid wood to veneer with plywood. The resulting layer can easily withstand small, medium and heavy loads. The recommended cost for retail stores is 1500 rubles. Country of origin - Switzerland.

- Fast drying;

- Compatible with almost all types of coatings;

- Easy to apply;

- It can work both on the first and on the finish line.

- Limited fit for use on chipboard.

Instead of an epilogue

A study of the range of fixing varnishes on the Russian market found that most of it is occupied by the lower price segment, represented by a domestic manufacturer.Budget prices are explained only by the small volume of the container in which varnishes are supplied, because they are primarily intended for fixing / repairing various damages, rather than for fixing decor applied to furniture. Moreover, these samples are applied with a brush and, with rare exceptions, are sprays. The middle segment was divided both in terms of price and quality. For repair work, the buyer prefers Russian high-quality aerosols, and for large-scale work, Western samples are already selected, which are applied either with a roller or with a large brush. The price for both is about the same. The premium class is represented exclusively by foreign-made universal sprays, which have a considerable cost and are capable of both fixing decorative patterns and performing repair tasks.

new entries

Categories

Useful

Popular Articles

-

Top ranking of the best and cheapest scooters up to 50cc in 2025

Views: 131649 -

Rating of the best soundproofing materials for an apartment in 2025

Views: 127688 -

Rating of cheap analogues of expensive medicines for flu and colds for 2025

Views: 124517 -

The best men's sneakers in 2025

Views: 124031 -

The Best Complex Vitamins in 2025

Views: 121938 -

Top ranking of the best smartwatches 2025 - price-quality ratio

Views: 114978 -

The best paint for gray hair - top rating 2025

Views: 113393 -

Ranking of the best wood paints for interior work in 2025

Views: 110318 -

Rating of the best spinning reels in 2025

Views: 105327 -

Ranking of the best sex dolls for men for 2025

Views: 104363 -

Ranking of the best action cameras from China in 2025

Views: 102214 -

The most effective calcium preparations for adults and children in 2025

Views: 102010